Imagine you're an engineer in a bustling automotive lab, surrounded by humming electric motors and intricate prototypes. You've spent weeks designing a cutting-edge EV motor, but when it comes to rigorous testing, your current dynamometer setup is letting you down—inconsistent results, frequent calibrations, and that nagging downtime eating into your deadlines. Sound familiar? It's a common pain point in industries where precision is non-negotiable. But what if there was a solution that not only eliminates these headaches but also elevates your testing to new heights of accuracy and reliability? Enter the hysteresis brake dynamometer—a game-changer that's quietly revolutionizing how we validate performance in motors, engines, and beyond. In this deep dive, we'll explore why this technology is the unsung hero of modern testing, how it works its magic, and why forward-thinking teams are making it their go-to tool. So, grab a coffee, settle in, and let's unlock the future of dependable testing together.

First off, let's demystify what a hysteresis brake dynamometer actually is. At its core, it's a specialized device used to apply controlled braking forces during performance testing. Unlike traditional mechanical or hydraulic dynamometers that rely on friction or fluid dynamics, hysteresis brakes leverage the fascinating physics of magnetic hysteresis. Picture this: when a magnetic field interacts with a conductive material, like a steel disc, it induces eddy currents that create resistance—essentially, braking without physical contact. This non-contact approach is key. For instance, in motor testing, the dynamometer attaches to the shaft, simulating real-world loads while measuring torque, speed, and power with astonishing precision. It's like having a silent, invisible partner that never wears out, ensuring every test run is spot-on repeatable.

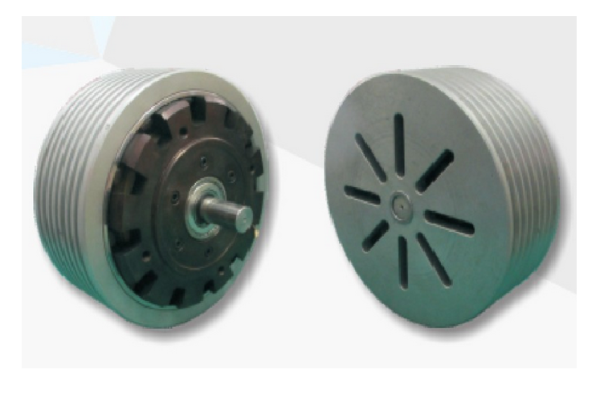

Now, how does it all work under the hood? Let's break it down simply. A hysteresis brake dynamometer consists of a rotor (usually a disc made of magnetic material) and a stator with coils that generate a magnetic field. When the rotor spins, the magnetic field induces those eddy currents we mentioned, producing a braking force proportional to the current applied to the coils. The beauty here is the control: by adjusting the electrical input, you can fine-tune the braking torque instantly, across a vast speed range—from near-zero RPMs to high-velocity spins. This linear response means no sudden jerks or lag, making it ideal for dynamic testing scenarios. Plus, since there's no physical wear like in friction-based systems, maintenance is minimal. Think of it as a \"set it and forget it\" solution that hums along reliably for years, even in harsh environments.

Why should you care? Well, the advantages of hysteresis brake dynamometers are nothing short of transformative. For starters, they deliver unparalleled accuracy. In torque testing, for example, they achieve resolutions down to fractions of a Newton-meter, catching even the tiniest inefficiencies in motor designs. This precision isn't just nice to have—it's critical in sectors like automotive R\u0026D, where a slight miscalculation could mean recalls or missed efficiency targets. Another huge win is their broad operating range. Whether you're testing a low-speed industrial gearbox or a high-revving aerospace turbine, these dynamometers handle it all without breaking a sweat. And let's talk reliability: with no consumable parts or lubrication needed, downtime plummets. One client, a leading EV manufacturer, slashed their calibration cycles by 80% after switching, freeing up precious engineering hours for innovation instead of upkeep.

The applications are as diverse as they are impactful. In the automotive world, hysteresis brake dynamometers are indispensable for validating everything from hybrid powertrains to regenerative braking systems. They simulate real driving conditions, helping engineers optimize for fuel efficiency and emissions compliance. Over in renewable energy, they're vital for testing wind turbine generators, ensuring they withstand fluctuating loads without hiccups. Even in consumer electronics, they play a role in fine-tuning small motors for drones or appliances. Don't just take my word for it—consider the case of TechDrive Innovations. They were struggling with inconsistent results in their drone motor tests, leading to costly redesigns. After integrating a hysteresis brake dynamometer, their failure rate dropped by 60%, and time to market accelerated. As their lead engineer put it, \"It's like we finally have a crystal ball for performance—predictable, dependable, and utterly indispensable.\"

But wait, how does it stack up against alternatives? Traditional eddy current or water brake dynamometers have their place, but hysteresis brakes shine in scenarios demanding smooth, consistent control. For instance, eddy current models can suffer from heat buildup and torque ripple, while hysteresis units offer cleaner, more stable output. Hydraulic dynamometers? They're powerful but messy, with fluid leaks and high maintenance costs. Hysteresis brakes, by contrast, are compact, quiet, and eco-friendly—no oils or coolants to manage. That makes them a smarter choice for labs prioritizing sustainability and cost efficiency. Plus, their digital integration is seamless, hooking up effortlessly with modern data acquisition systems for real time analytics. It's not just an upgrade; it's a leap toward future proofing your testing infrastructure.

Of course, no technology is perfect, and it's fair to address potential concerns. Some might worry about initial costs or electromagnetic interference in sensitive setups. However, the long term savings in reduced maintenance and improved accuracy quickly offset the investment. And with advanced shielding options, interference is easily mitigated. The key is choosing a reputable supplier who offers robust support and customization—because one size doesn't fit all in precision testing.

So, what's the next step? If you're ready to transform your testing from a chore to a competitive edge, it's time to explore hysteresis brake dynamometers. Reach out to our team for a personalized demo, where we'll showcase how this tech can solve your specific challenges. Whether you're in automotive, aerospace, or industrial manufacturing, the path to flawless performance starts here. Don't let outdated methods hold you back—embrace innovation that works as hard as you do.

In closing, hysteresis brake dynamometers aren't just tools; they're enablers of excellence. They empower engineers to push boundaries, innovate fearlessly, and deliver products that stand the test of time. As industries evolve toward smarter, greener solutions, this technology will only grow in relevance. So, why wait? Join the ranks of visionaries who've already made the switch, and experience testing redefined. Your breakthrough is just a dynamometer away.

And remember, in a world where every watt and RPM counts, precision isn't a luxury—it's a necessity. Let's build that future, one reliable test at a time. 👏🔧